| Customers: Saransk heating networks (formerly SaranskTeploTrans) Contractors: CIRCLE OF NPF Product: CAS KRUG-2000Second product: SCADA KRUG-2000 Third product: DevLink-C1000 Industrial controllers Project date: 2016/10 - 202/10

|

Content |

| The project team from the customer | Integrator Consultant |

| не указана | Salitov Artem (Head of APCS Department) Vartanov Vartan (Chief Project Engineer) Sergey Murashov (APCS Engineer) Igor Dolgushev (APCS Engineer)

|

2025: Reconstruction of central heating points

In Saransk, the reconstruction of two central heating points (CTP) was carried out with the replacement of corrective pumps and weather control units. NPF Krug announced this on November 28, 2025.

Saransk heating networks (a branch of Mordovian PJSC T Plus) carry out activities to transport thermal energy to the population, budgetary institutions and other consumers in the city of Saransk. As of November 2025, 756 km of heating networks and centralized hot water supply, 13 pumping stations, 104 central heating points are on the balance sheet.

The employees of KRUG as part of the commissioning works at the Central Process Center 2-8 S/Z and Central Process Center Banya Center performed the following works:

- controller equipment reprogramming,

- update the application software on the servers of the automated dispatch control system (ADMS) of the DPT,

- connection of new control cabinets of correcting pumps and control valves to the ADCS, which use frequency converters to control the temperature of the supplied network water and to ensure the temperature schedule of heating at positive outdoor air temperatures.

DTC control cabinets are equipped with industrial DevLink-C1000 controllers together with I/O modules of the DevLink-A10 series, which collect and primary processing of data with their further transmission via the GSM channel to the upper level of the system - to the Dispatching Center of Saransk heating networks. Control center workstations operate under the control of the Russian SCADA KRUG-2000.

The performance of these works allows the dispatching personnel of Saransk heating networks to monitor the quality of the supplied resource to consumers, monitor the state of the technological process and equipment in real time, and remotely control the operation of pumps and other equipment of the TSC.

The reconstruction of the TsTP was carried out by RMK LLC (Kstovo, Nizhny Novgorod Region). The company "KRUG" has carried out commissioning works in terms of DCS ADMS.

2021: Connection of all heat points of Saransk

All thermal points of Saransk are connected to a single digital control system. This was announced on March 9, 2021 by NPF Krug.

As of March 2021, all 103 TSCs are integrated in the automated dispatch control system SaranskTeploTrans Mordovian of the branch "."T Plus

The main goal of the project is to increase the economic efficiency of the heating networks of Saransk due to the transition to the "deserted technology" of the CTP management.

Constant operational control of heating network parameters, timely detection of heat losses and possible leaks ensures high-quality supply of heat and hot water to consumers.

SaranskTeploTrans is part of the Mordovian branch of T Plus PJSC. CTPs provide network water for heating and hot water to residential areas of Saransk. In total, in 2020, T Plus invested 380 million rubles in the reconstruction of heat supply and water supply networks in Saransk.

The automated dispatching control system (ADMS) of the SaranskTeploTrans TSC operates on the basis of the software and hardware complex of the KRUG-2000 CAS.

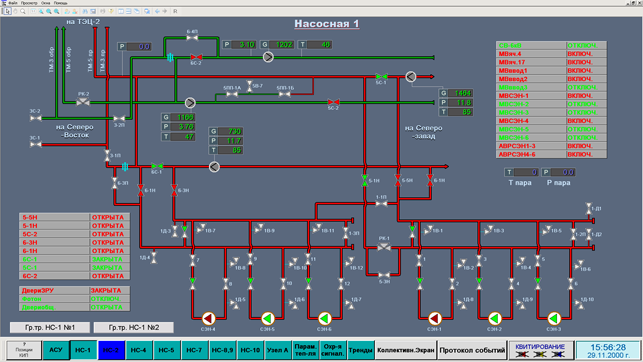

The WS of the system dispatcher under the control of the Russian SCADA KRUG-2000 collects the data of the main process parameters of heat supply from the control cabinets of the TSC and provides the issuance of remote control commands to them. Information from control cabinets is also transmitted to the existing telemetry system SaranskTeploTrans.

Information exchange between the DevLink-C1000 controllers installed on the DTC and the dispatcher AWS is carried out via a redundant GSM/GPRS communication channel using a GSM modem built into the controllers with support for 2 SIM cards.

The project was prepared within the framework of the Rubin-Automation consortium, which unites OJSC NPP Rubin (part of the Rostec structure) and LLC NPF KRUG. The consortium carried out a full range of work on the implementation of the system:

- design of control cabinets and upper level of the system

- delivery of software and hardware complex

- Installation and commissioning activities.

2019

Increase in the number of fully automated central heating points in Saransk to 27

On September 2, 2019, Krug announced that the number of fully automated central heating points (CTPs) in Saransk increased to 27 in 2019. In September, work will be completed on the technical re-equipment of four more CTPs on the street. Likhachev, st. Sevastopol, st. Yaroslavskaya and st. Volodarsky.

KRUG has also prepared design documentation for the automation of two TSCs on Marinin Street and Sovetskaya Street. These systems are developed using the KRUG-2000 software and hardware complex (CAS KRUG-2000).

SaranskTeploTrans JSC is part of the Mordovian branch of T Plus PJSC. CTPs provide network water for heating and hot water to residential areas of Saransk.

I&C CPTs are designed for remote monitoring of coolant parameters, control of process equipment and are developed using standard technical solutions of KRUG company: I&C of heat stations and ASDU facilities of the heat supply company.

Microprocessor controllers DevLink-C1000 with I/O modules of the DevLink-A10 series provide control of pumps and electric drives of electrified shut-off and control valves, collection, processing of information from temperature, pressure and flow sensors of coolant and actuators.

TSCs are equipped with metering units for network water, HWS and HWS to take into account the heat energy and coolant supplied to the consumer, as well as cold water for heating, ventilation, hot water supply, and technological needs.

Information from the control cabinets is transmitted to the WS of the central control room dispatcher and to the existing telemetry system of the Central Process Center of SaranskTeploTrans JSC. The control cabinets provide the possibility of process monitoring using the local control panel based on the operator touch panel.

KRUG has extensive experience in developing design documentation for APCS, which makes it possible to easily replicate our solutions for automation of heating network companies.

Project of automation of thermal and raising stations in Saransk

On June 10, 2019, Krug announced the development of design documentation of automation systems for two pumping stations (thermal and boosting) for heating networks in Saransk. These systems are an extension of the existing ASDU pumping stations of SaranskTeploTrans OJSC, operating on the basis of the KRUG-2000 software and hardware complex (CAS KRUG-2000).

SaranskTeploTrans JSC is part of the Mordovian branch of T Plus PJSC and supplies thermal energy to Saransk, operation and repair of urban heat supply systems.

Thermal pumping station No. 14 with a capacity of 2200 m³/ch is located in the area of ul. Volgogradskaya. The source of heat supply is Saransk TETs-2. Four centrifugal pumps (2 operating and 2 standby) are installed in the pump station.

Boost pump station No. 11 with a capacity of 3750 m³/ch. designed to supply thermal energy to residential areas. The source of heat supply is Saransk TETs-2. Five centrifugal pumps are installed in the pump station (3 operating pumps, 1 for repair and 1 standby).

APCS of pump stations has been developed using typical technical solutions of KRUG company: APCS of pump stations and ASDU facilities of heat supply company.

Microprocessor controllers DevLink-C1000 with DevLink-A10 series I/O modules provide ESN control, collection, processing of information from temperature, pressure and coolant flow sensors, power converters and actuators. The control cabinets provide the possibility of process monitoring using the local control panel based on the operator touch panel. AWS 1 and AWS 2 located in the control room operate under the control of SCADA KRUG-2000.

To improve the reliability of operation, the system uses 100% hot redundancy of communication channels. The main channel is Ethernet, the backup channel is GSM/GPRS.

Start-up of automatic data collection system

On March 11, 2019, KRUG put into operation a system for automatic data collection (SDA) from gas metering stations of SaranskTeploTrans JSC on the basis of the CAS KRUG-2000 software and hardware complex.

At the first stage, 14 boiler houses are included in the SDA system from gas metering stations.

The system provides:

- data collection from gas flow correctors YeK-260/270 in real time

- improving the accuracy of accounting due to reducing the size of the imbalance of natural gas in the main areas of use

- efficiency of mutual financial calculations for natural gas supply/consumption

- reduction of technological and commercial losses due to timely detection of excess consumption.

The following works were performed by the research and production company KRUG:

- design of control cabinets and upper level of the system

- delivery of software and hardware complex

- installation and commissioning supervision.

The system was developed using standard technical solutions for APCS of boiler houses and natural gas metering. In 2019, it is planned to expand the system with the connection of all boiler houses of SaranskTeploTrans JSC.

2017

Connection of "Autoremzavod Saransk" to dispatching system "SaranskTeploTrans"

On November 20, 2017, KRUG announced the commissioning of the central heat center of the Autoremzavod Saransk microdistrict to the current automated dispatch control system (ASDU) of SaranskTeploTrans OJSC.

The control cabinet of the TSC was delivered as part of the project on the technical re-equipment of the telemechanics system and telecontrol of the central heat centers "SaranskTeploTrans."

The central heating point of the Avtoremzavod microdistrict was built and put into operation to replace the outdated boiler house. All commissioning work was carried out by NPF KRUG before the start of the heating season.

DSC control cabinets were developed on the basis of a standard technical solution - APCS of thermal stations. An industrial DevLink-C1000 controller with DevLink-A10 series I/O modules from the KRUG-2000 software and hardware complex was used as controller equipment.

APCS modernization of pump stations

On February 27, 2017, KRUG announced the automation of pumping stations for heating networks in Saransk as part of the project for the construction of the Mordovia Arena stadium.

KRUG supplied two control cabinets for automation of pumping stations of heating networks in the city of Saransk as part of the project "Construction stadium with 45,000 seats, Saransk, st. Volgogradskaya. Heat supply networks ":

- booster pump station on the street. Sushchinsky

- thermal pumping station on the street. Volgograd.

PCS of pump stations is integrated into the dispatching control system of pump stations of JSC SaranskTeploTrans, developed on the basis of a standard technical solution of NPF KRUG for pumping stations of heating networks.

Pump station control cabinets are equipped with industrial DevLink-C1000 controllers and DevLink-A10 series I/O modules. SCADA KRUG-2000 is used as the control technology.

2016

Project development

On December 15, 2016, KRUG announced the automation of the heat supply pumping station of the Yubileiny district of the city of Saransk. The Yubileiny district will include five residential districts of the city.

ASDU is integrated with the existing integrated automated dispatch control system for pump stations of JSC SaranskTeploTrans on the basis of a standard technical solution of NPF KRUG for pump stations of heating networks.

The APCS core is a control cabinet with industrial DevLink-C1000 controllers and DevLink-A10 series I/O modules, they provide:

- control of mains electric pumps

- monitoring the condition of pumps and gate valves

- collection and processing of information from sensors, metering devices and actuators (data from sensors of coolant temperature, pressure and flow rate).

The control cabinet provides the possibility of process monitoring using the local control panel based on the operator touch panel.

The reliability of the system provides 100% hot redundancy of the processor modules of the DevLink-C1000 controllers and 100% redundancy of communication channels.

The software used is POSCADA KRUG-2000. AWS are organized using console structures of ConsErgo series.

2015

Project development

On July 3, 2015, it became known about a project to increase the functionality of the automated dispatch control system for pumping stations of JSC SaranskTeploTrans on the platform of the software and hardware complex. KRUG-2000 (CAS KRUG-2000) The work under the contract for the supply of telemetry cabinets was performed by the company. "CIRCLE"

The objectives of the ASDU expansion are:

- possibility of remote control of network electric pumps (SES)

- increased reliability of the system due to application of 100% hot backup of controller equipment DevLink-C1000

- increasing the computing power of the system by adding DevLink-A10 series I/O modules.

Functions:

- switching on and off SEP

- collection and display of information on the process progress and condition of pump stations equipment on monitors of automated workstations of dispatchers and a collective use screen

- monitoring of heat carrier temperature and hydraulic parameters

- monitoring of pump station voltage input currents, EPC currents, power consumption and EPC bearing temperature

- maintenance and archiving of parameter trends, reporting documents, event protocols.

ASDU by pumping stations of JSC SaranskTeploTrans on the basis of CAS KRUG-2000

KRUG, as part of the work to transfer the heat load of the central boiler house to Saransk TETs-2 and transfer the control room heating networks from the territory of the central boiler house to the territory of SaranskTeploTrans OJSC, introduced an automated dispatch control system for pump stations based on the KRUG-2000® software and hardware complex (KRUG-2000® CAS).

PROJECT OBJECTIVES

- Providing operational personnel with timely, reliable and sufficient information on the process progress and condition of the main equipment for the possibility of operational control

- Optimization of equipment operating modes

- Technical reporting.

Functions

- Collection and display of information on the process progress and condition of pump stations equipment on the monitors of automated workstations of dispatchers and the display of collective use

- Monitoring of temperature and hydraulic parameters

- Data archiving.

PROJECT MILESTONES

System structure The system of automated dispatch control of pump stations of JSC SaranskTeploTrans is developed on the basis of the software and hardware complex KRUG-2000®. When creating the system, a typical technical solution of NPF KRUG was used for pumping stations of heating networks.

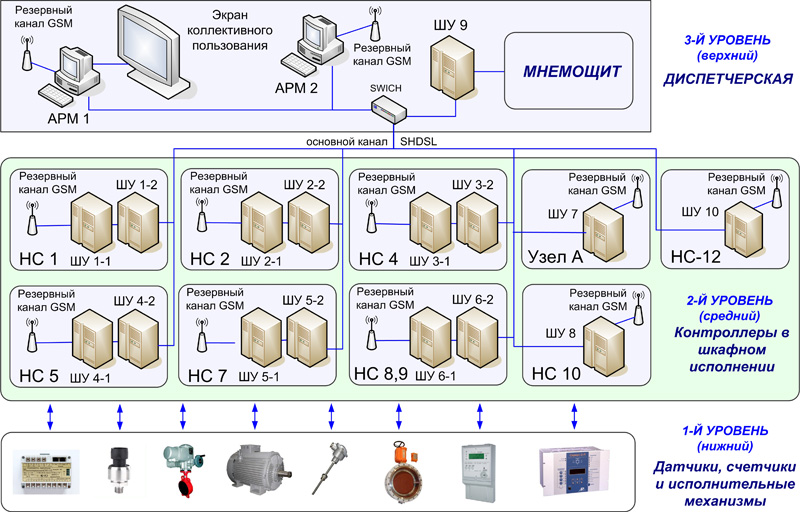

The structure is a three-level architecture:

The 1st (lower) level includes sensors of measured parameters, shutoff and control valves, pumps.

The 2nd (middle) level of the system is represented by the controller equipment installed in the control cabinets (ShU) of seven pump stations (SS). Microprocessor controllers DevLink-C1000 with I/O modules of the DevLink-A10 series provide the collection, processing of information from sensors and actuators: monitoring the state of pumps and valves, data from sensors of temperature, pressure and coolant flow. The control cabinets provide the possibility of process monitoring using the local control panel based on the operator touch panel.

The 3rd (upper) level of the system is represented by two automated workstations of the dispatcher (ARM1, ARM2) under the control of SCADA KRUG-2000® and a collective screen. ARM1, ARM2 are combined in functions with 100% redundant database servers that collect, process visualization and long-term storage of data coming from the middle level of the system.

To improve the reliability of operation, the system uses 100% redundancy of communication channels. The main channel is SHDSL (telephone lines), the backup channel is GSM/GPRS. Communication is carried out using a specialized protocol that allows you to work with slow and unreliable communication channels.

Information power of the system

- Analog inputs - 161

- Discrete input signals - 1916.

System features

- 100% hot protection of communication on different types of channels (SHDSL - main, GSM/GPRS - standby)

- Remoteness of control facilities, communication with which is carried out via telemechanical protocol (TM channel).

PROJECT EFFECT

Implementation will ensure that:

- improving the reliability of equipment operation by reducing the probability of erroneous actions of personnel

- increased reliability of information collection due to duplication of communication channels

- increased availability of equipment.

Development prospects lie in the possibility of expanding the functionality of the system:

- increasing the functionality of existing pumping stations

- scaling of the system with connection of other pumping stations.

The specialists of NPF KRUG have completed the installation of cabinets, engineering and commissioning. At the beginning of 2015, it is planned to include in the system of pumping station No. 10 with 100% redundancy of processor parts of the controller and communication channels.

CUSTOMER

SaranskTeploTrans is part of the Mordovian Branch of Volzhskaya TGK OJSC and supplies thermal energy to Saransk, operation and repair of urban heat supply systems.

KRUG has been working at SaranskTeploTrans OJSC since 2010. During this time, 18 central heating points (CTP) were put into operation. In 2014, six sets of equipment were shipped for the modernization of the TsTP of the North-West, Central and South-West regions of Saransk. SCADA KRUG-2000® software and upper-level equipment for APCS of hot water boilers of TVG-8 station No. 1 and No. 2 of the third microdistrict and boiler of TVG-8 station No. 2 of the sixth microdistrict of Saransk were supplied.